Waste Plasma Gasification Process

Product Details:

Waste Plasma Gasification Process Price And Quantity

Product Description

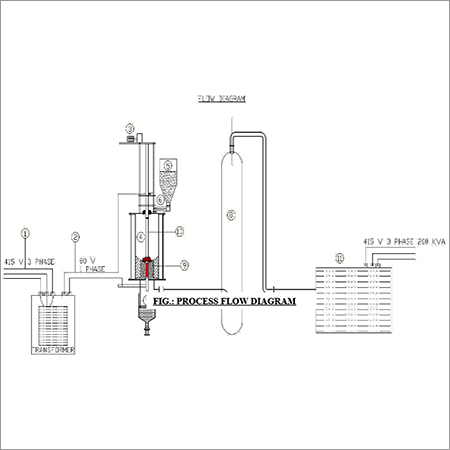

Block Diagram of Waste Plasma Gasification Process

Generation of Syngas through Plasma Gasification is ideal for the treatment of:

- Plastic waste

- Hospital waste

- Municipal solid waste

- Tannery waste

- Wood and paper waste

- Organic waste

- Oil sludge & Tar

- Coal fines

- Hotel waste

- Colony waste

- Any other carbonaceous waste

Procedure

This process is a drastic non-incineration thermal process, which uses extremely high temperatures in an oxygen-starved environment to completely decompose input waste material into very simple molecules. The intense and versatile heat generation capabilities of plasma technology enable a plasma gasification/ vitrification facility to treat a large number of waste streams in a safe and reliable manner. Dioxin and furan compounds are not expected to be present in the syngas from gasifiers for two reasons. First, the high temperatures in the gasification process destroy any dioxin or furan compounds or precursors in the feed. Secondly, the reducing environment precludes the formation of free chlorine from HCl, thereby limiting chlorination of any species in the syngas. The by-products of the process are a combustible gas and an inert slag. Plasma gasification consistently exhibits much lower environmental levels for both air emissions and slag leachate toxicity than other thermal technologies.

Advantages

Decomposition of waste into energy-rich fuel having calorific value of 13 MJ/Kg.

Because of the oxygen starved atmosphere and high temperature, the base elements of the gas cannot form toxic compounds such as furans, dioxins, NOx, or sulfur dioxide in the reactor.

Product gas is rich in CO, hydrogen and light hydrocarbons. The product gas contains substantial sensible heat, which is amenable for heat recovery to improve the efficiency of the electricity generation subsystem. A typical composition of this gas is 2443% (v/v) H2, 2544% (v/v) CO, 1026% (v/v) CO2 and N2, depending mainly on the waste input composition. It is suitable for use as a fuel gas for turbines or gas engines.

Total replacement of petroleum fuel for the net energy output

The slag is usable as aggregate, rock-wool, etc.

Large volume reduction, the slag is 1/250th of the volume of the processed solid waste.

No harmful emission or leachate

As plasma converted gas can be combusted in gas turbines, higher conversion efficiencies can be achieved. Although the conversion efficiency cannot meet that of a combined cycle plant, because power has to be fed back to the gasifier, conversion efficiency will normally be greater than for a utility boiler system.

Technical Specifications

- Feed rate: 100kg/hr max

- Feed size: 8mm

- Syngas o/p : 300KW max (based on plastic raw material) gross.

- Water requirement: 20 ltrs /hr

- Power requirement: 80 KW ( from self generation)

- Consumables: Traversing electrode 1 no / month

- Fixed base block 2 no/ year

High-Efficiency Clean Energy from Waste

Utilizing plasma gasification, this process transforms waste materials into valuable syngas with high energy content. Its innovative technology minimizes emissions and produces safe, inert slag, supporting sustainable waste management and energy recovery goals for urban and industrial settings.

Modular, Automated, and Scalable Solution

The systems modular configuration allows for seamless scale-up, accommodating diverse operational needs. With fully automated PLC/SCADA-based controls, it enables efficient, reliable, and safe continuous operation, while significantly reducing manual intervention and operational risks.

Minimal Environmental Footprint

Real-time gas cleaning technology guarantees ultra-low emissions, addressing stringent regulatory requirements. The vitrified slag by-product is inert, drastically reducing landfill requirements and offering opportunities for reuse, contributing to a cleaner and safer environment.

FAQs of Waste Plasma Gasification Process:

Q: How does the Waste Plasma Gasification Process achieve high conversion efficiency?

A: The system leverages extreme plasma temperatures (1,200C to 5,000C) to completely break down organic and inorganic waste, achieving up to 99% waste destruction. This ensures maximum conversion of waste into syngas and minimizes residue output.Q: What type of feedstock can be processed with this technology?

A: It is engineered to handle a wide range of feedstock, including municipal solid waste, industrial waste, and hazardous waste, making it a versatile solution for diverse waste management challenges.Q: When is it suitable to implement this process in a waste management strategy?

A: This technology is ideally adopted in scenarios where waste minimization, energy recovery, and stringent emission standards are priorities. Its particularly beneficial for urban, industrial, and hazardous waste streams.Q: Where can the Waste Plasma Gasification Process be applied?

A: The process is suitable for installation in municipal solid waste treatment plants, industrial facilities, hazardous waste disposal centers, and renewable energy projects across India and other regions seeking sustainable waste solutions.Q: What are the main benefits offered by this technology?

A: Key advantages include high-calorific syngas production for energy use, minimal land-fill requirements due to vitrified slag, ultra-low emissions, and scalability to meet demand. It supports regulatory compliance and fosters resource recovery.Q: How are emissions controlled during the process?

A: Emissions are managed with advanced real-time gas cleaning systems that ensure ultra-low pollutant release, supporting compliance with environmental regulations and protecting community health.Q: What utility requirements are needed for operation?

A: The primary utility needed is a reliable electricity supply for the plasma torches. The control system operates automatically with PLC/SCADA, streamlining operations and reducing manpower needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese