Gas Producer Plant Instrumentation

Product Details:

- Product Type Gas Producer Plant Instrumentation

- General Use Industrial gas generation and monitoring

- Material Mild Steel/SS Fabrication

- Type Industrial Process Instrumentation

- Capacity From 50 Nm3/hr up to 1000 Nm3/hr (customizable)

- Computerized Yes, integrated computerized system

- Automatic Fully automatic operation

- Click to View more

X

Gas Producer Plant Instrumentation Price And Quantity

Gas Producer Plant Instrumentation Product Specifications

- Gas Producer Plant Instrumentation

- Mild Steel/SS Fabrication

- As per customer requirement (varies by model)

- Customizable as per plant design

- Grey & Blue (customizable)

- Approx. 10 kW to 50 kW (depending on size)

- From 50 Nm3/hr up to 1000 Nm3/hr (customizable)

- Fully automatic operation

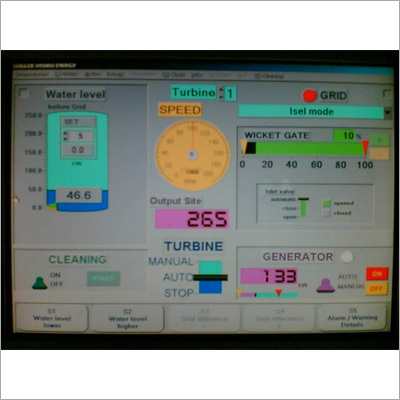

- PLC based automatic control with HMI panel

- 3 Phase, 415 V, 50/60 Hz

- Yes, integrated computerized system

- From 1200 kg and above

- High and low pressure ranges available (up to 20 bar)

- Water cooled system

- Up to 99%

- Industrial Process Instrumentation

- Depends on capacity; e.g. ~20 Nm3/hr for standard units

- Industrial gas generation and monitoring

Product Description

Assisted with highly skilled team of technical experts, we are involved in offering Instrumentation of Gas Producer Plant services to the clients across the nation. We are well equipped with advanced software systems and techniques that enable us to render these services in configured way. All the instrumentation, maintenance and repairing work is performed under the observation of our experts with the help of advanced tools and technology in order to provide efficient functioning of plants. In addition, our clients can get these Instrumentation of Gas Producer Plant services from us at pocket friendly rates.

Advanced Control System for Precision

Equipped with a modern PLC-based automatic control system and a user-friendly HMI panel, the instrumentation enables precise, real-time management of gas production processes. This automation reduces manual intervention and augments plant safety while enhancing efficiency through seamless process monitoring and data acquisition.

Customizable Production Capacity

Whether you require 50 Nm3/hr or a scale-up to 1000 Nm3/hr, the gas producer plant is configurable to match your specific volume demands. This flexibility accommodates a range of industrial applications, from moderate to large-scale requirements, ensuring a tailored solution for every client.

Sturdy and Reliable Construction

The systems fabrication in mild steel or stainless steel ensures long-lasting performance under demanding industrial conditions. Its water-cooled architecture enhances operational safety and protects key components, supporting uninterrupted, high-quality gas generation.

FAQs of Gas Producer Plant Instrumentation:

Q: How does the automated control system enhance efficiency in the gas producer plant?

A: The plant features a PLC-based automatic control system, integrated with an HMI panel, allowing for continuous process monitoring, automated adjustments, and fault detection. This automation minimizes manual intervention, optimizes operational parameters, and increases both accuracy and plant productivity.Q: What is the highest pressure that the instrumentation can handle?

A: The instrumentation offers high and low pressure ranges, handling pressures up to 20 bar, making it suitable for a variety of industrial gas generation and monitoring applications.Q: When should I consider customizing production capacity or purity levels?

A: Customization is ideal during the planning or design phase to match your plants gas demand and required purity levels. The system can be tailored for capacities between 50 Nm3/hr and 1000 Nm3/hr with adjustable purity of up to 99%, based on your specific industry requirements.Q: Where is this gas producer plant typically installed?

A: This system is suited for industrial environments across India, ranging from manufacturing units to chemical processing plants, where reliable on-site gas generation and monitoring are essential.Q: What is the process for installing and commissioning the plant?

A: Installation follows customer-specific dimensions and capacity requirements, with the manufacturer or distributors technical team providing all necessary onsite support for setup, calibration, and system integration to ensure seamless start-up and operation.Q: How does the water-cooled system benefit plant operation?

A: The integrated water cooling system helps manage heat loads generated during gas production, protecting sensitive instrumentation and ensuring consistent performance even under continuous operation.Q: What are the usage advantages for industrial clients?

A: Clients benefit from high reliability, advanced automation, scalable capacity, and robust construction, all of which support uninterrupted gas supply and minimize maintenance, making the system highly suitable for continuous industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Gas Plants ' category

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese