Plasma Gasification

Product Details:

- Product Type Plasma Gasification Plant

- General Use Waste treatment, Energy generation

- Material Mild Steel, Stainless Steel

- Type Industrial Waste Processing Equipment

- Capacity From 50 kg/hr up to 50 tons/day

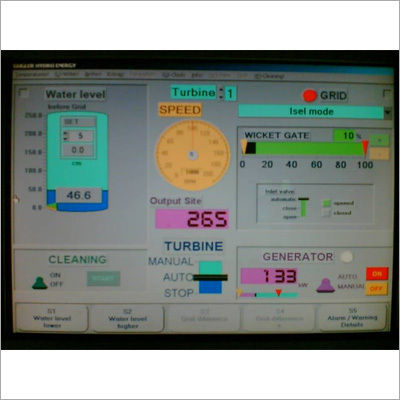

- Computerized Yes

- Automatic Fully automatic

- Click to View more

X

Plasma Gasification Price And Quantity

Plasma Gasification Product Specifications

- PLC-based advanced control system

- Waste treatment, Energy generation

- High-efficiency plasma torches, Low environmental impact

- Industrial Grey (custom colors available)

- Varies by feedstock, up to 1500 Nm/hr syngas

- From 50 kg/hr up to 50 tons/day

- Approx. 15,000 - 40,000 kg (varies by model)

- Atmospheric or slight positive pressure

- Industrial Waste Processing Equipment

- Up to -40C

- Yes

- Customizable; Example: 6m x 3m x 4.5m

- Mild Steel, Stainless Steel

- Fully automatic

- 415 V / 3 phase / 50-60 Hz

- As per plasma torch specification, typically 75-300 Nm/hr

- 300 kW - 2 MW (depending on plant size)

- Syngas CO and H2 purity up to 99%

- Water cooled/forced air cooled system

- Plasma Gasification Plant

Product Description

Plasma Gasification is a process for breaking the chemical bonds and destroy any kind of solid or liquid organic waste, PCBs (polychlorinated biphenyls), asbestos and hydrocarbons prior to dumping them in landfills or traditional mass-burn incinerators. This is done so as to remove any hazardous effects of organic wastes that may be dangerous for humans and animals. This process can be used for treatment of various types of wastes such as tannery, wood & paper, coals, oil sludge & tar, municipal solid waste, etc. We offer Plasma Gasification service to our valued patrons at a cost-effective price.

Features:

-

Creates low pollution

-

Large volume reduction of solid waste is possible

-

Completed within stipulated time frame

Advanced Waste Processing Technology

Utilizing DC transferred or non-transferred plasma torches, our system efficiently gasifies a variety of waste streams at temperatures up to 1600C. It handles hazardous, industrial, municipal, and medical wastedelivering flexibility and reliable sterilization while minimizing environmental risk.

Syngas and Resource Recovery

With production rates reaching up to 1500 Nm/h, plasma gasification yields high-purity syngas (CO and H2 up to 99%), which can be used for energy generation or chemical synthesis. The process also recovers valuable metals and produces vitrified slag, suitable for construction or safe disposal.

Automated Control and Remote Access

Fully automated and computerized, the facility features a PLC-based advanced control system and touchscreen HMI interface for intuitive operation. Remote SCADA/internet monitoring, interlocks, and safety protocols ensure optimal performance and secure operation at all times.

FAQs of Plasma Gasification:

Q: How does the plasma gasification process handle different types of waste feedstock?

A: The plasma gasification system is engineered to accept hazardous, medical, municipal, and industrial wastes. Its high operating temperatures and advanced plasma arc technology ensure that diverse feedstocks are thoroughly broken down into syngas, vitrified slag, and recoverable metals, providing both safety and efficiency.Q: What benefits does syngas from plasma gasification provide?

A: Syngas produced, primarily composed of hydrogen and carbon monoxide with trace methane, can be utilized for power generation, chemical synthesis, or further energy conversion. Its high purity (up to 99%) and customizable output rates make it a valuable resource while significantly reducing landfill waste.Q: When is the plasma gasification system ready for operation from a cold start?

A: The system reaches operational temperatures within 30-60 minutes from a cold start, enabling quick ramp-up and flexible scheduling for waste processing operations.Q: Where can plasma gasification systems be installed?

A: These systems are designed for indoor industrial installations, suitable for climates with ambient temperatures between 0C and 50C and up to 85% relative humidity. Dimensions and layout are customizable to fit client facility requirements across India or for international export.Q: What process ensures environmental compliance and emission control?

A: Our equipment incorporates a multi-stage filtration and scrubbing system that removes airborne contaminants from exhaust gases. This advanced emission control meets stringent environmental standards while maintaining efficiency in waste destruction.Q: How is operation and maintenance managed for maximum uptime?

A: Automated with a PLC-based control system and equipped with touchscreen HMI, routine tasks are streamlined for operators. Major maintenance is required bi-annually, with safety and emergency shutdown interlocks ensuring secure operation throughout the year.Q: What integration and usage options does this technology offer?

A: The plasma gasification system offers flexible integrationworking in hybrid configurations with existing incinerators or turbine generators to boost overall efficiency. Its modular design accommodates a wide range of waste treatment and energy generation requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Gas Plants ' category

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese