Plasma Arc Gasification

Product Details:

- Product Type Plasma Arc Gasification System

- General Use Waste to Energy, Hazardous Waste Disposal

- Material Mild Steel, Stainless Steel

- Type Industrial Waste Processing Equipment

- Capacity 10 - 100 TPD

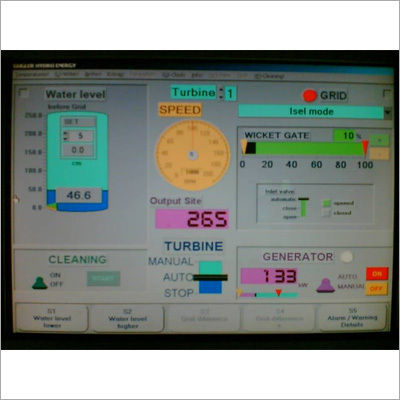

- Computerized Yes

- Automatic Yes

- Click to View more

Plasma Arc Gasification Price And Quantity

Plasma Arc Gasification Product Specifications

- Standard Atmospheric

- 10 - 100 TPD

- Yes

- Customized, typically 15m x 5m x 6m

- Water Cooling

- Up to 99%

- High temperature operation, minimal residual waste, low emission

- PLC Based

- Up to 85% Syngas Conversion

- Mild Steel, Stainless Steel

- Waste to Energy, Hazardous Waste Disposal

- Yes

- Plasma Arc Gasification System

- Depends on Feedstock, typically 1-2 Nm3/min

- -40C

- Industrial Waste Processing Equipment

- 350 800 kW/h

- 20000 65000 kg

- 380 440 V

- Grey or Customized

Product Description

Based in Kolkata, West Bengal, we are a 2005-established company engaged in offering quality based Plasma Arc Gasification service to our widely scattered clients. This process is widely used for garbage treatment prior to dumping them in landfills. It uses both electricity and high temperatures to turn garbage wastes into usable by-products. This is done without any kind of burning so it ensures low pollution and a healthy environment. One more advantage of this process is that it reduces the amount of waste sent to landfills and also generates some electricity. We offer Plasma Arc Gasification service at a cost-effective price.

Features:

-

Good for environment

-

Substantial reduction in the amount of waste

-

Eliminates harmful and hazardous substances

Advanced Waste-to-Energy Solution

Plasma Arc Gasification employs cutting-edge plasma torch technology to convert diverse waste streamsincluding municipal, industrial, and medical wasteinto valuable syngas. Its robust design and flexibility accommodate varied feedstock and high moisture content, ensuring continuous operation in challenging conditions. This system is engineered for sustainability, offering minimal residual waste and low emissions.

Flexible and High-Efficiency Operation

With a processing capacity of 10100 TPD and syngas conversion rates up to 85%, this solution integrates seamlessly into existing infrastructures. Its PLC-based automation supports both full and partial control modes, while multi-stage wet/dry gas scrubbing guarantees emission compliance with EU and US EPA standards. Water cooling maintains optimal operational stability.

Global Support and User-Focused Design

After-sale service is available worldwide, ensuring reliable maintenance and quick support for all installations. The system features remote monitoring, customizable sizing, noise levels below 75 dB at 1 meter, and accommodates various voltage and air requirements, making it suitable for installations across diverse geographies and industries.

FAQs of Plasma Arc Gasification:

Q: How does plasma arc gasification process different types of waste?

A: The system uses a high-temperature plasma torch (up to 1 MW) to thermally decompose municipal solid, industrial, or medical waste into syngas and an inert slag. Temperatures from 1200C to 3000C enable the conversion of heterogeneous, high-moisture feedstocks (up to 30% moisture content) with minimal residual ash.Q: What benefits does syngas production offer in waste-to-energy applications?

A: Produced syngas, rich in hydrogen and carbon monoxide, serves as a versatile fuel for power generation, chemical synthesis, or hydrogen production. With syngas purity reaching up to 99% and conversion rates as high as 85%, the system supports both energy recovery and environmental sustainability goals.Q: When and where is plasma arc gasification most effectively used?

A: This technology is ideally deployed in industrial estates, municipal waste treatment facilities, and healthcare zones dealing with hazardous or high-volume waste. Installation typically takes six to ten months, after which the system delivers over 20 years of reliable operation.Q: What emission compliance and cleanup features are included?

A: The plant integrates a multi-stage wet/dry gas scrubber and advanced monitoring systems to ensure gaseous emissions meet or exceed EU and US EPA standards. This guarantees safe operation and regulatory compliance, even with challenging feedstocks.Q: How is the equipment controlled and monitored during operation?

A: A computerized, PLC-based control system manages automation levelseither fully or partially, according to user preference. Remote monitoring capabilities allow real-time oversight of performance and diagnostics, improving efficiency and safety.Q: What is the residue output after gasification, and how is it managed?

A: Less than 5% of the input material is converted to inert, non-leachable slag. This residue is environmentally safe and can often be repurposed in construction or safely disposed of, drastically reducing landfill dependency.Q: What support is available after installation, and how is ongoing usage ensured?

A: Comprehensive global after-sales serviceincluding maintenance, troubleshooting, and spare partsis provided. Regular inspection and technical support help maintain uptime and system longevity, ensuring efficient waste management for decades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Gas Plants ' category

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |