Waste Plasma Gasifier

Product Details:

- Product Type Waste Plasma Gasifier

- General Use Solid Waste Disposal & Energy Generation

- Material Stainless Steel

- Type Horizontal

- Capacity 5-50 TPD (Tons Per Day)

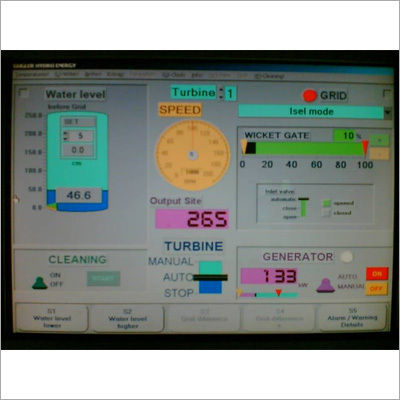

- Computerized Yes

- Automatic Yes

- Click to View more

X

Waste Plasma Gasifier Price And Quantity

Waste Plasma Gasifier Product Specifications

- 1500 Nm3/hr

- PLC Based

- Waste Plasma Gasifier

- High Efficiency, Low Emissions, Modular Design

- Solid Waste Disposal & Energy Generation

- -40C

- 99.9 (Syngas purity)

- 150-450 kW per module

- 20000-45000

- Water Cooled

- Horizontal

- Yes

- 5-50 TPD (Tons Per Day)

- Customizable, Typical 6m x 3m x 4m per module

- 380-440V, 3 Phase

- Ambient

- Grey & Blue

- Yes

- Stainless Steel

- Adjustable, up to 95% waste conversion

Product Description

Established in 2005, we are a Kolkata-based company engaged in manufacturing and supplying of Waste Plasma Gasifier. It is designed and fabricated using supreme quality components and sophisticated technology by our dexterous team of professionals. We offer this gasifier in different models and technical specifications as per requirements of our clients. Provided gasifier is used for converting organic matter into synthetic electricity, gas, and slag by the use of plasma. Moreover, we offer this Waste Plasma Gasifier at most reasonable rates to the clients.

Features:

-

Rugged construction

-

Optimum performance

-

Long service life

Efficient Waste Conversion and Energy Recovery

Harnessing plasma torches at temperatures of 1200C to 1600C, this gasifier transforms up to 95% of mixed waste streams into high-purity syngas. The process ensures minimal residue by producing vitrified inert slag and incorporates advanced controls for optimal efficiency and safety.

Flexible and Automated System Integration

Available as modular, skid-mounted, or fixed installations, this automated system is adaptable for diverse environments. Featuring a user-friendly touch screen HMI and PLC-based controls, operators can manage processes with ease while maintaining high operational standards and low emissions.

Sustainable Waste Disposal and Compliance

Designed for adherence to international environmental norms, the gasifiers auxiliary systemsincluding robust gas cleaningensure exhaust emissions remain well below regulatory limits. Bi-annual maintenance, water-cooling, and high-grade materials contribute to both operating reliability and environmental responsibility.

FAQs of Waste Plasma Gasifier:

Q: How does the Waste Plasma Gasifier convert waste materials into energy?

A: The Waste Plasma Gasifier employs a DC Plasma Torch to heat waste materials to temperatures of 1200C to 1600C, breaking them down into basic molecules. This generates syngascomposed mainly of CO and H2which can be used for energy generation while producing vitrified inert slag as residue.Q: What types of feedstock are suitable for processing in this gasifier?

A: This system is designed to process a broad variety of feedstocks, including municipal solid waste, industrial waste, hazardous materials, and other refuse. Its robust construction and high tolerance for mixed waste streams make it versatile for different waste disposal needs.Q: When is maintenance required, and how complex is the process?

A: Maintenance is scheduled on a bi-annual basis. The system incorporates PLC-based automated controls and an accessible design, allowing for efficient inspection, component replacement, and cleaning, minimizing operational downtime.Q: Where can the Waste Plasma Gasifier be installed?

A: It offers installation flexibilitycapable of being skid-mounted for easy relocation or fixed for permanent operations. The modular dimensions and customizable design make it suitable for a variety of industrial or municipal sites across India and international markets.Q: What is the start-up time for this plasma gasifier system?

A: The typical start-up time for the unit is between 2 and 3 hours, during which it reaches operational temperatures and stabilizes its automated systems for optimal waste conversion and energy generation.Q: How does the system ensure environmental compliance during operation?

A: Equipped with advanced gas cleaning and slag removal systems, the gasifier maintains exhaust emissions within global environmental standards. Automated monitoring and controls ensure consistent performance and minimal environmental impact.Q: What are the main benefits of using the Waste Plasma Gasifier for solid waste disposal?

A: Key benefits include high waste conversion rates, recovery of valuable syngas for energy, low emissions, minimal residue, low operational noise, and the adaptability of installation. Its automated, PLC-based controls ensure ease of usage and high system reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Gas Plants ' category

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese