Plasma Gasifier

Product Details:

- Product Type Plasma Gasifier

- Material Mild Steel/Stainless Steel

- Type High Temperature Gasification

- Capacity Up to 500 TPD

- Computerized Yes

- Automatic Yes

- Purity(%) Up to 99% (Syngas Output)

- Click to View more

Plasma Gasifier Price And Quantity

Plasma Gasifier Product Specifications

- Up to 500 TPD

- Low Emissions, High Efficiency, Remote Monitoring

- Low/Depends on Feed

- Plasma Gasifier

- Up to 99% (Syngas Output)

- Yes

- High Temperature Gasification

- Mild Steel/Stainless Steel

- Approx. 45,000 kg

- Yes

- Up to 500 TPD

- Custom/Standard Grey

- Atmospheric or Slightly Negative

- 400 kWh/ton waste (typical)

- Customized (e.g., 7m x 3m x 4m)

Product Description

Outfitted with an up to date facility, we are the most famous manufacturer and supplier of a broad array of Plasma Gasifier. This gasifier is assembled using supreme quality components and sophisticated technology by our dexterous team of professionals. In line with different requirements of our clients, we provide the offered gasifier in varied specifications. Provided gasifier is used for converting organic matter into synthetic electricity, gas and slag by the use of plasma. Moreover, we offer this Plasma Gasifier at most reasonable rates to the clients.

Features:

-

Rugged construction

-

Optimum performance

-

Long service life

-

Low power consumption

Details:

Generation of Power through Plasma Gasification Of Plastic Waste, In collaboration with CMERI, CSIR Production and consumption of plastics have increased significantly due to its flexibility, durability and economy. But the disposal of plastic waste is a major threat creating environmental hazards. Nearly 40 wt% of the same can be recycled whereas the balance 60 wt% needs a careful disposal. The problem of safe disposal of plastic waste, together with the increasing cost of petroleum products, has encouraged research on the possibility of their conversion into useful forms of energy or chemical products. With this background Central Mechanical Engineering Research Institute (CMERI), Durgapur CSIR National Research Laboratory under the aegis of Department of Scientific & Industrial Research, Govt. of India has under taken a project Generation of syngas through plasma gasification of plastic sponsored by Petroleum Conservation Research Association (PCRA), Ministry of Petroleum & Natural Gases, Govt. of India. Positronics India has joined hands with CMERI and will be launching the product for commercial use soon. Positronics India has taken the principle of gasification of plastic to a extent of using not only plastic but ANY CARBONASIOUS material. It can be food waste, dry leaves, wood, saw dust etcetera, that too, without any segregation. A mixture of any carbonaceous material available can be crushed and fed to the gasifier. In return we get green power. MERITS: 1) Ability to accept a wide range of opportunity fuels with limited preprocessing requirements. 2) Operation at ambient pressures allowing for simple feed systems and online maintenance of the plasma torches. 3) Low gas velocities allowing for greater feed flexibility and eliminating most expensive pre-treatments of feed stock. 4) Environmentally friendly operation since syngas that is created has very low quantities of NOx, SOx, dioxins and furans. 5) Inorganic components get converted to molten slag which is removed as vitrified by-product safe for use as a construction aggregate. 6) It can have wide application in Industries, Municipality, Hospitals, society and domestic usage. HENCE PLASTIC IS NO MORE A POLLUTANT BUT A CHEAP SOURCE OF POWER.

Advanced High-Temperature Gasification

The Plasma Gasifier utilizes advanced plasma technology to achieve efficient high-temperature gasification. This process ensures the breakdown of various waste materials into valuable syngas with high purity. Low emissions and optimized energy consumption distinguish it as an environmentally conscious and cost-effective solution for waste-to-energy conversion.

Flexible Capacity and Custom Design

With a capacity of up to 500 tons per day and customizable dimensions, the plasma gasification system is engineered to accommodate different operational demands and site constraints. Its construction from either mild steel or stainless steel contributes to durability and longevity, while offering custom or standard grey exterior finishes for aesthetic adaptability.

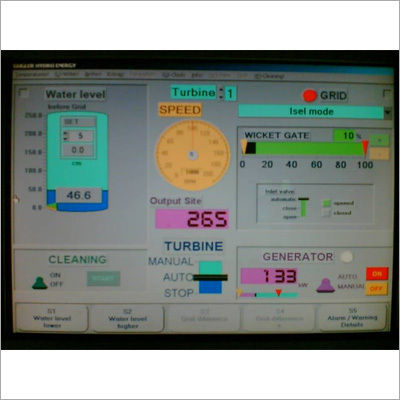

Smart Operation and Monitoring

Equipped with computerized controls and automatic functions, the Plasma Gasifier allows for seamless operation and precise process management. Remote monitoring enables operators to track system performance in real-time, ensuring reliability and delivering data-driven decision support for continuous optimization.

FAQs of Plasma Gasifier:

Q: How does the Plasma Gasifier operate to convert waste into syngas?

A: The Plasma Gasifier uses high-temperature plasma arcs to break down waste materials under atmospheric or slightly negative pressure. This process transforms the feedstock into high-purity syngas (up to 99%), minimizing emissions and residual by-products.Q: What range of materials can the Plasma Gasifier process?

A: The system can handle a variety of waste streams, including municipal solid waste, industrial refuse, and biomass. Its robust design ensures efficient gasification for both hazardous and non-hazardous feedstocks.Q: When is the Plasma Gasifier most beneficial for industrial operations?

A: It is particularly advantageous when there is a need for large-scale waste disposal integrated with energy generation, offering up to 500 TPD processing and reliable syngas output for energy or chemical production.Q: Where can the Plasma Gasifier be installed and used?

A: These systems are suitable for industrial plants, waste management facilities, and energy production sites across India. Customized sizing allows installation in varied environments, both urban and remote.Q: What is the typical process flow within this high-temperature gasification unit?

A: Waste enters the reactor, is exposed to plasma arcs that drive gasification at very high temperatures, producing a clean syngas and reducing the volume of residual ash. All operations are automated and computer-controlled for efficiency.Q: How is power and air consumption optimized in the Plasma Gasifier?

A: The system is engineered for low air intake and typical power consumption of about 400 kWh per ton of waste processed. These features help minimize operational costs and environmental impact.Q: What are the main benefits of using this Plasma Gasifier solution?

A: Key benefits include high syngas purity, minimal emissions, remote monitoring, customizable build, and robust automationmaking it ideal for sustainable waste management and energy recovery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Gas Plants ' category

|

POSITRONICS INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese